It is important to note that today’s cars are equipped with antipollution systems to reduce emissions of CO, CO2, NOx, HC, O2, etc.

These measurements are usually displayed in PPMs for hydrocarbons and as a percentage for carbon monoxide, carbon dioxide and oxygen.

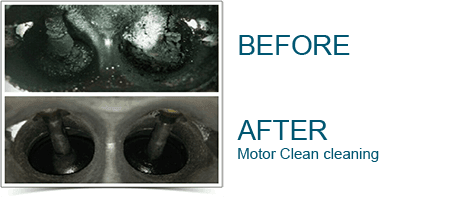

To limit pollution, cars are now equipped with EGR valves. The EGR (Exhaust Gas Recirculation) valve was invented in the United States to reduce NOx emissions by redirecting some of the exhaust gases into the intake circuit to burn it for a second time;

The particulate filter is part of the exhaust line but it is only present in diesel engines.

Placed after the catalytic converter, it eliminates other fine particulates composed mostly of carbon. Since February 1, 2011 it has been compulsory in new diesel vehicles.

It should be noted, however, that particulate filters can only operate at high temperatures, i.e. during long trips at high speed, and not during daily trips in the city. This post-treatment device is installed on the exhaust system to treat the exhaust gases, thus reducing their harmfulness. Catalytic effect by transforming certain gases into other less polluting components.

To ensure particulate filter efficacy, the temperature of gases must be around 500°C in order to allow spontaneous oxidation of the molecules.

The catalytic converter is also part of your exhaust system and is useful for gasoline engines and for diesel engines in the fight against polluting emissions.

For a vehicle that runs on gasoline, a catalytic converter referred to as a “3-way” catalytic converter is used that turns nitrogen dioxide and carbon monoxide into a less polluting or non-polluting substance.

For a vehicle with a diesel engine, a 2-way catalytic converter is used to convert unburned hydrocarbons and carbon monoxide in order to release harmless water, nitrogen and carbon dioxide.

It has a “honeycomb” structure consisting of a ceramic monolith made of precious metals such as palladium and uses incoming exhaust gas and engine heat to produce chemicals.